Decorative Concrete

Decorative concrete is the use of concrete as an aesthetic enhancement to a structure, while still serving its function as an integral part of the building itself such as floors, walls, driveways, and walkways.

Cast-in-place Concrete

Homestead Paving specializes in Cast-In-Place (CIP) concrete. Cast-in-place concrete is a building construction method where we use locally supplied ready mix concrete that meets the customers mix design parameters.

Concrete Pavement

What is Paving? Well, in its most basic form, a concrete pavement is an extruded slab of concrete made from cement, aggregate, sand, and water and no other company understands this process better than Homestead Paving.

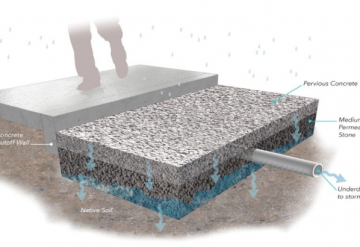

Pervious Concrete

Homestead Paving is the recognized leader in pervious concrete in the southern Florida region. Pervious concrete is an important product for our area, and it is critical that all the proper installation methods are followed in order to deliver a quality long lasting result.